My father’s spaceship

Tell us a story about little known fact about yourself. §

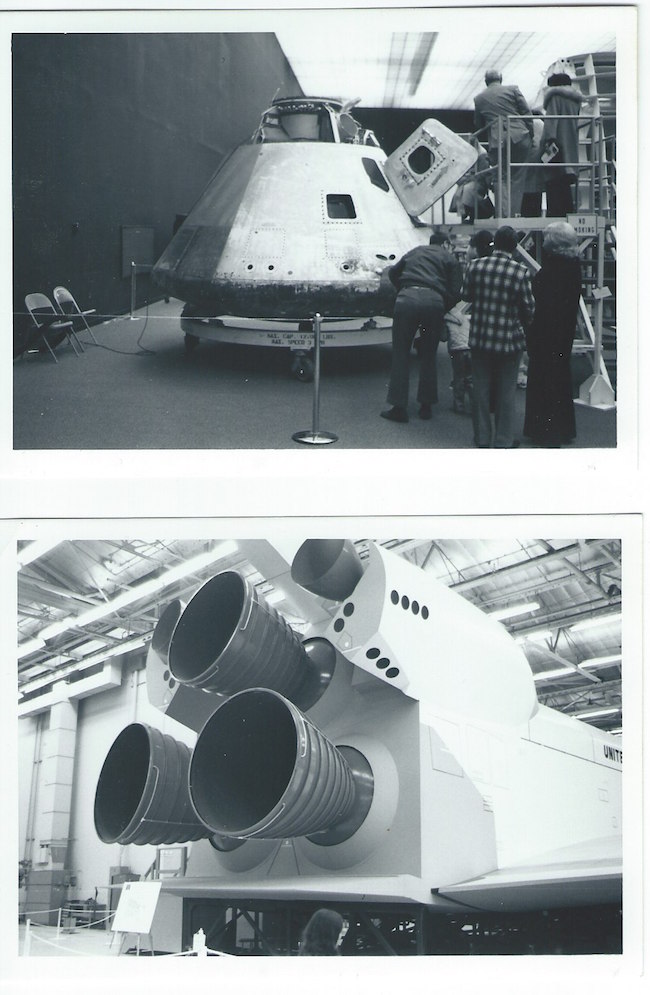

A little known fact about me is: my father built spaceships.

Building spaceships takes a lot more than what’s shown in the movies and news. Today media focuses on the strong personalities that drive a space program. This is new.

In the recent past, before the NASA resurgence we’re seeing today. Before the ISS, even. Before the private investment in spaceflight we have. There was the Space Shuttle.

“Was he a rocket scientist? An engineer, maybe?”

No. People with those jobs don’t build spaceships. They might say they do, but they don’t. They design spaceships. My father was a union Toolmaker. He worked on the shop floor, and deciphered the blueprints handed down from on high.

As a toolmaker, he spent most of his life working in the Jig & Fixture devision of the major aerospace companies of the 1970s and 80s. Jobs moved with the government contracts, but most stayed in the Southern California “rocket belt.” A costal area that stretched from El Segundo to Long Beach did most of the country’s aerospace production. By the mid-90s the jobs and some of the companies had dried up. He retired in 1992, just before the crash happened.

The jigs and fixtures that he built were used to align parts on the production line. Suppose an airplane wing needs to be attached to its fuselage. On the assembly line the workers can’t just hold it up and bolt it on. Each part sits in its own fixture, and they are guided together with a jig that controls the when and where of the meeting. Then the assembly can continue.

The largest project he ever worked on was the Space Shuttle Orbiter. Rockwell International had the contract, and times were good. Everyone eats good when there’s government overtime on the menu. Before the shuttle, there was the Apollo missions to the moon.

I grew up hearing work stories around the dinner table. Not stories of space. Stories of metal. My father’s space program was steel, aluminum, and titanium. It was the metal that became the foundation of dreams for the future.

As the space program waned, defense work keep the factories churning. Rockwell’s signature project of the 1980s was the B-1B Bomber. Resurrected from the failed B-1A project and destined to replace the aging B-52, the B-1B became my father’s last great project. The overtime flowed, and I hardly saw him during daylight hours. The Air Force contract was for 100, and the tooling needed to be ready for the new assembly line.

Once the B1-B tooling was out the door, he worked on other contracts. Nothing ever came close to the heyday of the Space Race and Cold War.

The job of traditional toolmaker doesn’t exist today. It’s been replaced by computers and automation. CAD/CAM programs can solve a manufacturing problem on a screen. Robot arms act as both jig and fixture with a few lines of code.

It was a different time. There was no trade schools teaching the skills of the shop floor. The skills that turned a blueprint into finished tooling were learned on the job. It was a hard-knock apprenticeship on the government dime. He made his career on projects that defined two eras of American history. I don’t know if someone with a seventh-grade education could do that today.

Note: the photos in this post are original scans from my personal archive. This is the first time they’ve ever been online.